Vertical Farming: Changing Cannabis Cultivation

DRM Design is no stranger to the cannabis industry. With nearly a thousand successful projects and permits across the country, their deep knowledge in facility design and cultivation operations has helped growers maximize efficiency and production, whether they’re launching a startup or scaling up a commercial enterprise.

One of the biggest shifts they’re seeing in the industry is the rise of vertical farming. It’s not just about stacking plants to save space—it’s about engineering a smart, scalable system that supports healthy plant growth, consistent yields, and streamlined operations. In this blog, we’ll explore what makes vertical farming successful, why it’s catching on fast, and how DRM’s designs help cultivators get it right from the start.

Why Vertical Farming?

Space is at a premium, especially in cannabis indoor farms. Whether you’re retrofitting an old warehouse or building a new facility, every square foot counts. That’s where vertical farming comes in.

Instead of growing on a single level, vertical farming offers one, two, or even three more tiers of growing plants, all stacked within a controlled environment. The goal? Increase output without expanding your physical footprint.

But it’s not as simple as stacking shelves. “The cornerstone of success in vertical farming transcends the mere act of stacking plants; it lies in mastering the shades of airflow, lighting, and the intricate interplay of every component within the spatial ecosystem,” says Nic Bucholz, CEO of DRM.

Without the right design, vertical systems can run into major issues, like uneven airflow, temperature swings, and mold outbreaks. It takes precision to create an environment where every plant, on every tier, gets exactly what it needs.

More Than Just Space: Creating an Ecosystem That Works

Traditional single-tier systems are popular for a reason: they’re simple and more forgiving when it comes to airflow and climate control. But as prices per pound drop and competition tightens, growers are looking for ways to produce more without spending more or increasing their operating costs.

Enter two-tier and even three-tier systems. By doubling or tripling production in the same footprint, these systems increase output and improve margins. But with that increase comes complexity.

“If you don’t get airflow right from the start, you’ll always be playing catch-up,” Nic warns. That’s because poor airflow leads to microclimates—small pockets of humidity and temperature variations that can stress plants or invite pathogens. To counter this, many growers are now shifting from traditional mixed airflow systems to more advanced rolling air systems. These provide consistent airflow across all levels, reducing risk and improving plant health.

Airflow Myths: More Isn’t Always Better

A common misconception is that simply adding more fans or ceiling fans will improve airflow. But without a thoughtful strategy, too much airflow can create turbulence, dry out plants, or cause inconsistent temperatures across tiers.

Successful airflow systems work like this: they create a blanket of consistent, uniform air movement that gently flows through the canopy. This ensures every plant receives the same conditions, regardless of height or location.

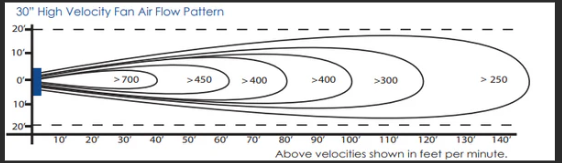

An area fan, for instance, is a fluid pump. On the back side of the fan the blades spin and create a void or negative pressure. The byproduct of that negative pressure is the output or discharge air on the other side, blowing across the room. Placing the fan too close to a call will restrict the air needed to fill the void supplying the output and reduce the performance of the fan. A solution would be to pull the fan away from the wall or object, or reduce the fan size or cfm (cubic feet per minute used to determine the performance rating of a fan) to allow for optimum performance. The same is for the output discharge side; too close to an object or wall, you prohibit the ability for the fan to work at its full potential. Food for thought, even though a fan might be rated at a throw distance of 20′ on paper, does not mean it will actually move the correct volume of desired cfm at that distance. Most manufacturers have a range scale that looks like a candle flame, which identifies the distance a fan will throw air. Plan to layout out the fan based on the first and second values, or around half the total distance, and you will see the desired results in the application.

Designing for Efficiency: DRM’s Approach

Good vertical farming design starts with good planning. DRM has fine-tuned their vertical farming guidelines to match the realities of today’s cannabis cultivation needs:

- Flower Tier Heights: Now typically set between 6–8 feet. This is up from the original 5–6 feet, giving more room for airflow and lighting setups.

- Vegetative Tier Heights: Usually between 5–7 feet, depending on strain. Previously, these were around 3–4 feet, but added height allows for more robust plant growth.

- Room Height: Old designs topped out around 14–16 feet, but with today’s tech, 18–22 feet is the new standard. This allows for modern lighting systems, HVAC equipment, and airflow configurations that make vertical systems work.

And placement matters. “A well-planned facility is not simply about maximizing production; it is about empowering the grower with uncompromised control over the environment,” says Nic.

Choosing whether to put HVAC systems inside or outside the grow room, for example, has a big impact. Internal setups save space but require more advanced airflow to manage heat. External systems offer better climate control but need more infrastructure. DRM helps growers navigate these trade-offs to find the right balance.

Lessons from the Field: Real-World Success

The best vertical farming setups are tailored to each grower’s space, goals, and strains. Here are a few examples:

- Ohio Facility: A 65,000-square-foot commercial grow opted for a tall two-tier system. With the right airflow, LED lighting, and irrigation, they’ve scaled up quickly without compromising quality. After DRM performed an in-person inspection of the site, we were able to determine all the issues and reported those findings. Within a few weeks of making the recommended changes, the facility saw a steady increase of nearly a half-pound per light of production increase for under $20k.

- Northern California: A mid-height, three-tier system here focuses on precision irrigation and tight climate control. DRM was able to determine the cooling capacity and dehumidification equipment originally specified were adequate, but the fan and racking layout were poorly organized, resulting in nearly 20% loss of crop every harvest. With our feedback for a few hundred dollars the fans and dehus were reorganized and the loss of crop reduced to less than 1%.

- Southern California: In a more compact facility, a high-density, short-tier, two-level system proves that even tight spaces can support serious yields—if the design is smart. Every inch counts, so precision layout of the ducted package units with flush wall-mounted grilles and dehus in the entry aisle near the room doorway, coupled with properly sized and placed horizontal and vertical rack fans, allows for consistent product harvest yields.

These examples show there’s no one-size-fits-all approach. Success depends on building a system that works for your unique environment—and sticking to best practices around airflow, lighting, and system layout.

As Nic says, “Every facility has its own set of requirements, but ultimately, the grower is the deciding factor. You can engineer the most sophisticated design imaginable, but without the right people driving the operation, it’s destined to fall short of its potential.”

Read more about our real-world success stories and case studies here

Looking Ahead: Where Vertical Farming Is Headed

Vertical farming isn’t just a trend—it’s quickly becoming the norm. As the industry evolves, growers are turning to more advanced technologies, automation, and environmental controls to support multi-tier systems.

But technology alone isn’t enough. “Inefficiency is just another word for profit loss. Get your systems right from the start, and everything else will follow,” Nic emphasizes. That means thoughtful design, careful planning, and a willingness to adapt as new tools become available.

And while vertical systems dominate the current conversation, single-tier facilities still have a role. With new cutting-edge lighting and HVAC tech, they’re becoming more efficient than ever. For some growers, that might still be the best fit.

At DRM, they design with all of that in mind—creating flexible, scalable, high-performing spaces tailored to each operation’s specific needs.

If your facility is already built, there is still hope for success. Call us and we will figure out the ideal solution together.